Mastering the Crunch — Food Coatings for Enhanced Texture and Longevity

In different cooking methods like deep frying, air frying, and home delivery scenarios, maintaining a desirable texture over time is a challenge that many producers face. This is where specialized coatings come into play, offering a versatile solution for keeping fried foods, such as French fries, crispier for longer.

Why Coatings Matter

Over time, fried food items can lose their crunch, becoming soft and unappealing due to moisture migration. Coatings serve as a protective layer, ensuring crispiness long after they have left the fryer. The right coating can extend the holding performance of fried foods, making them ideal for various cooking and delivery scenarios.

Coatings offer several benefits:

- Extended Holding Performance: retaining crispiness and warmth, crucial for both home delivery and post-cooking scenarios.

- Structural Integrity: reducing the chances of breakage during transit or when handled.

- Enhanced Appearance: appetizing color and texture, even when prepared in an air fryer or after storing under a heat lamp.

- Versatile Texture Options: allowing producers to control the texture, from a light crisp to a hearty crunch, catering to various consumer preferences.

Key Ingredients in French Fry Coatings

When creating coatings for French fries, the selection of ingredients plays a pivotal role. The main components of a coating blend typically include starches, flours, and dextrins. Each ingredient contributes unique properties that influence the final product:

- Modified Starches & Dextrins provide better performance in high-temperature environments, helping to create a strong, thin layer around the fry, which reduces fat absorption during frying and helps maintain crispiness.

- Flours and Thickeners influence the batter properties for an optimal coating and pick up. The choice of flour or thickener affects the mouthfeel and appearance of the final product, ensuring the fries have a consistent and desirable texture.

Emsland Group’s Modified Starches & Dextrins

The Emsland Group offers a range of blends and single ingredients for food coatings. For instance, Embat® 2000 is a base blend consisting of modified starch, potato dextrin, flour and thickeners for optimal performance in various coated food systems.

The portfolio of single ingredients consists of modified potato starches like Emflo® KV 20 and Emflo® KVA 20, known for their heat stability and ability to form a regular surface free from blisters or irregularities. Emdex® potato dextrins are widely used for its ability to improve crispiness and create, in combination with the modified starches an excellent film on the food’s surface.

Images 1 & 2: Native Starch coating applied, which is not stable enough against high temperatures resulting in uncontrolled expansion, irregular surface and blistering.

Image 3: Modified starch coating applied, which, due to cross linking, is heat stable resulting in a regular surface and controlled expansion

Innovative Coating for Air Frying

Air frying has become increasingly popular due to its ability to produce fries with less oil, appealing to health-conscious consumers. However, air frying presents unique challenges in achieving and maintaining crispiness. The lack of oil means that traditional frying’s crisp-inducing heat transfer does not occur in the same way, often resulting in less crispy food. The right combination of modified starches and dextrins in the coating can mimic the textural benefits of deep frying, providing a satisfying crunch. For example, a coating blend like Embat® 11384, which is designed for home delivery, can be particularly effective in air frying. It ensures that the fried food comes out of the air fryer with a desirable texture and stays that way longer after cooking.

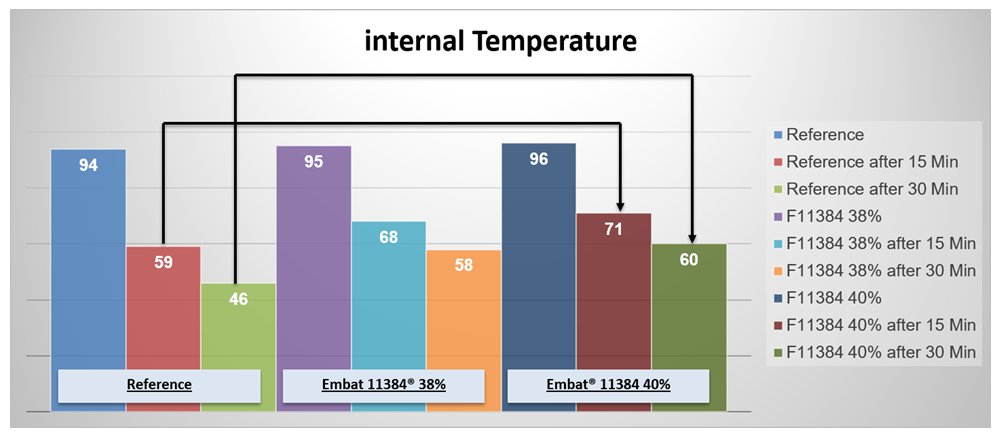

Figure 1: Trials showed that fries coated with Embat® 11384 had an internal temperature 10-12°C higher than those with standard coating formulations after 15 minutes of storage time in a box.

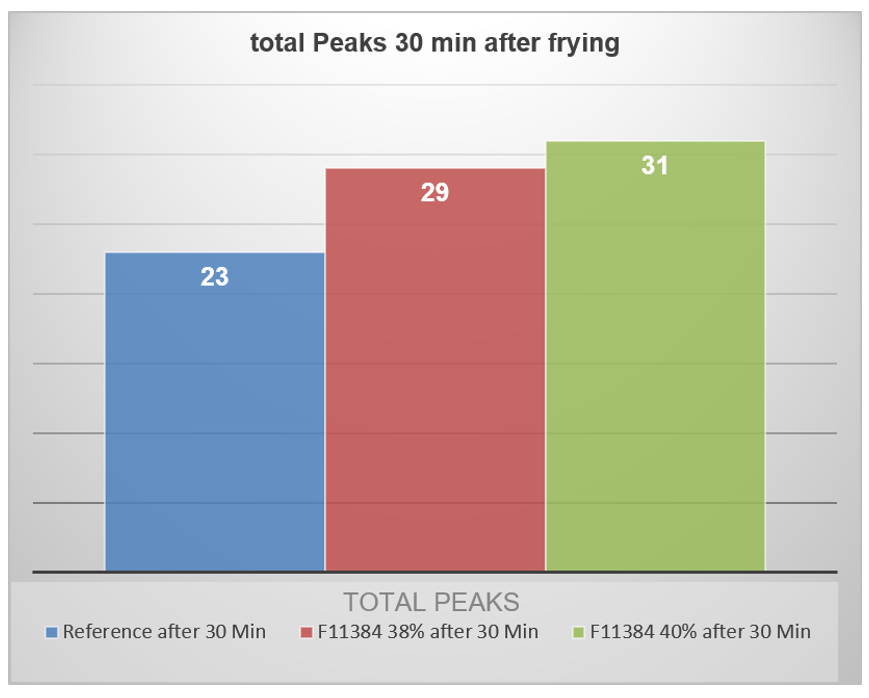

Figure 2: Trials also showed that fries coated with Embat® 11384 (38% and 40% batter concentration) retained peak surface crispiness for up to 30 minutes.

The Equipment Factor

The application of coatings requires specialized equipment. Wet coaters and continuous fryers are essential in ensuring that the coating is evenly applied and the products are cooked to perfection. The Emsland Group’s pilot plants provide producers to test and optimize the solutions to ensure the desired results are achieved before implementing into their own processes.

Conclusion

For fried food producers, the key to success lies in keeping the product crispier for longer, regardless of how it is cooked or served. Specialized coatings are an essential tool in achieving this, offering the versatility needed to meet the demands of this growing market. Whether your foods are destined for home delivery, served fresh from the fryer, or cooked in an air fryer, coatings are the secret to maintaining that all-important crispiness consumers crave.

Want to discover more articles like this? Sign up for our E-Newsletter INSIGHT